Control HQ system typically offers a return on investment within two to five years

Bedford College

Tomorrow's FM November 2019 - Degrees of Difference

Bedford College had issues with the cost and control of its heating and cooling systems – even after a major refurbishment of one of its buildings.

Bedford College, located in the South East Midlands, is the largest Further Education College in the region, serving students and apprentices aged 16 and above.

In an effort to showcase the application of alternative energy technologies and energy efficiency methods in existing buildings, the college retrofitted its Brundtland Building in 2012. Despite installing new gas boilers and a building energy management system (BEMS), the building still faced challenges regarding heating, cooling, and high energy expenses.

The Brundtland Building encompasses various facilities, including workshops, classrooms, and administrative offices. Similar to other buildings of this nature, it encountered common issues. For instance, the large workshops dedicated to bricklaying, carpentry, and electrical installation training proved challenging to heat adequately, and the presence of draughty windows exacerbated heat loss. The workshops relied on fan blowers connected to the new gas boilers for heat, but these blowers were both inefficient and noisy. Furthermore, they failed to distribute heat effectively, as the warm air quickly ascended to the ceiling.

The Bedford College classrooms faced their own set of problems. On warm days, they tended to overheat, while on cold days, they struggled to maintain sufficient warmth.

Some classrooms and offices were equipped with split-system air-conditioning units, which often operated simultaneously with radiators, resulting in substantial energy wastage. Moreover, due to the absence of timing controls, the air-conditioning units remained switched on overnight, even when unnecessary. This was especially problematic when staff worked late or classes were held during evenings or weekends, as the entire building had to remain heated.

THE RIGHT TO KNOW HOW

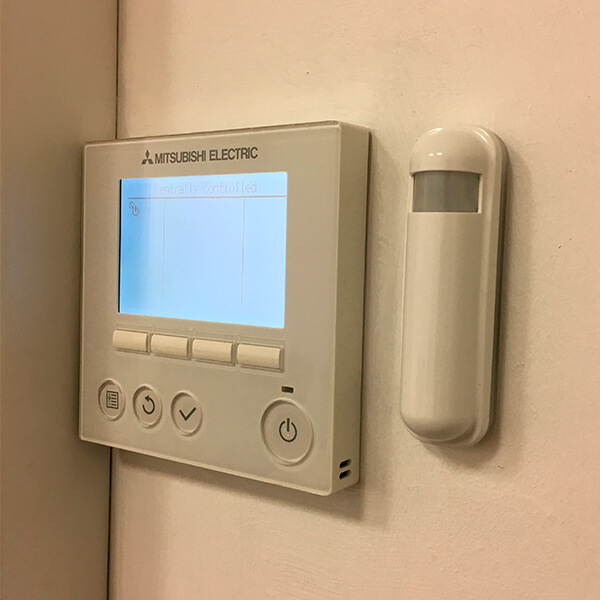

To address these issues, the college implemented a series of solutions. Intelligent room sensors that detect occupancy were installed in each room, along with modern double panel radiators equipped with smart thermostatic radiator valves (TRVs). This setup enables pre-heating of rooms prior to occupation and maintains a predetermined temperature during use. Once a room becomes unoccupied, the sensors automatically adjust the temperature to a setback level, conserving energy and reducing costs. In situations where staff members stay late or events take place outside regular hours, only the required rooms are heated, eliminating the need to heat the entire building.

To improve heating efficiency in the workshops, the fan blowers were replaced with wet overhead radiant panels. These panels emit heat downwards, directly providing warmth to the occupants. Like the rest of the system, the radiant panels are controlled based on room occupancy. Additionally, the existing air-conditioning units are now centrally controlled to prevent them from running simultaneously with the heating system or when the room is unoccupied.

BENEFITS OF INTELLIGENT CONTROLS

Implementing intelligent controls for heating and cooling systems offers numerous advantages, including significant cost savings and an improved learning and working environment within the featured building. Bedford College has specifically chosen Control HQ as the controls supplier due to its wireless equipment, allowing for quick and easy installation with minimal disruption to existing systems. Typically, the installation process takes only a few days without affecting the normal operation of the building.

With the new controls in place, college staff and the maintenance team no longer need to manually adjust temperatures in the rooms. Any heating issues that arise can be conveniently addressed through the Control HQ app, accessible via a smartphone or computer web browser.

The Control HQ system also keeps a comprehensive record of room occupancy and temperature data, providing valuable insights to administrative staff regarding room usage patterns. Additionally, the system takes care of routine maintenance tasks such as exercising the pump and radiator valves during the summer, preventing seizing and sludge build-up. The Control HQ system typically offers a return on investment within two to five years.

Request A Quote

PRODUCTS & SERVICES

Enquiry form

Please fill out the form provided with all the necessary details for your enquiry, and we will get back to you as soon as possible.

Customer Reviews

Royal North of Ireland Yacht Club, Co. Down

“We have saved on average 45% on our gas consumption which has been vital during the current climate.”

The Belfry Hotel, Birmingham

"We were extremely pleased to calculate that the Control HQ has saved us 64% off our heating costs meaning that the system has about a 2 year payback on the cost of installation.”

The Mount Business & Conference Centre, Belfast

“The Smart Control system has saved 41% on our gas bills in the first month and 9% on our electricity.”

Sister Theresa, Siena Monastery, Drogheda

"So far we’ve calculated a drop in gas usage of 30% in April and 50% in May. With the motion sensors, there is a great deal of ability to control when and why the heat comes on".

Josh Firth

"Always wanted the Nest thermostat in our house and had said it from the start of our new build. Had some resistance from the spark about installing Nest. So was very thankfully to find Joe through Nest Pro-installer. Who came on site and set up the system. Nothing was a problem, excellent service!"

Our Locations

Belfast Office

2 Woodstock Link

Belfast

Northern Ireland

BT6 8DD

Dublin Office

51 Bracken Road

Sandyford

Dublin

Ireland

D18 CV48